Housing of jacking pipe coupling or inner-liner

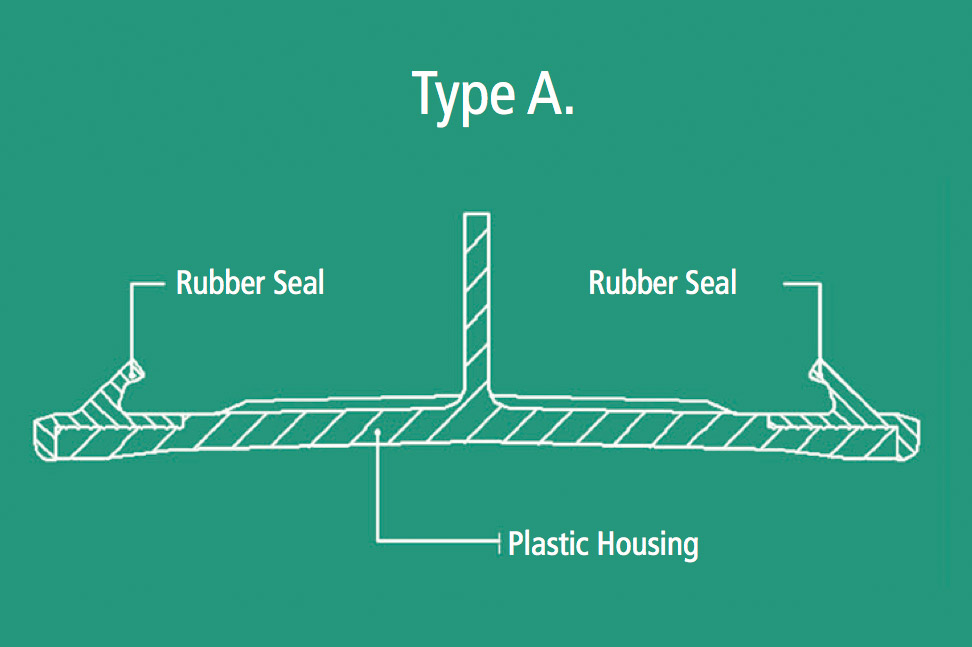

Depending on volume and size of the coupling the housing can be moulded (type A) or fabricated from steel (type B). For Type A for housing ABS or PP(GR) is generally used. The housing will satisfy all requirements of EN 295 part 1.

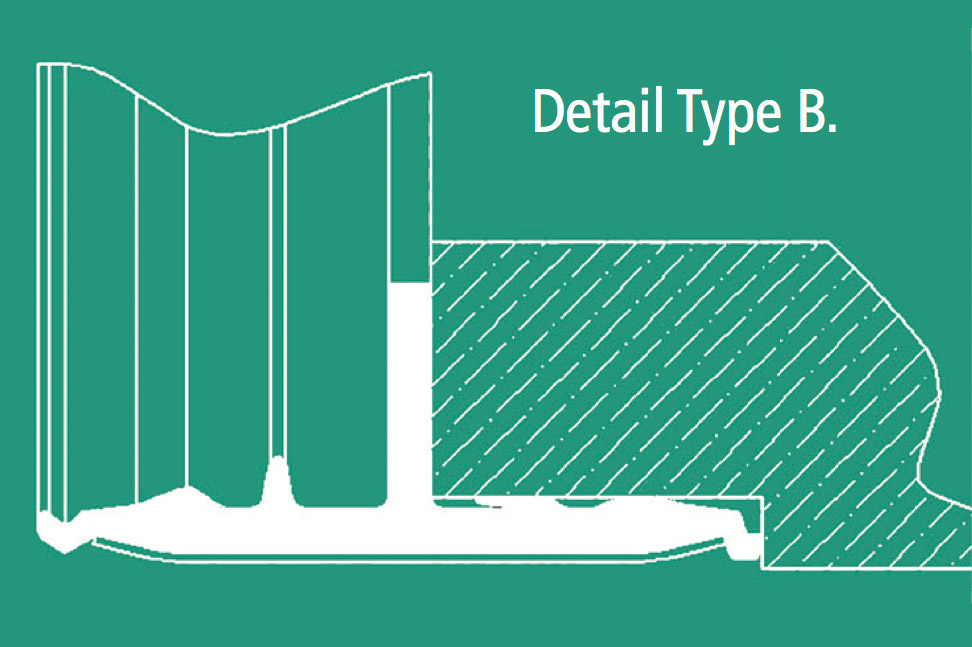

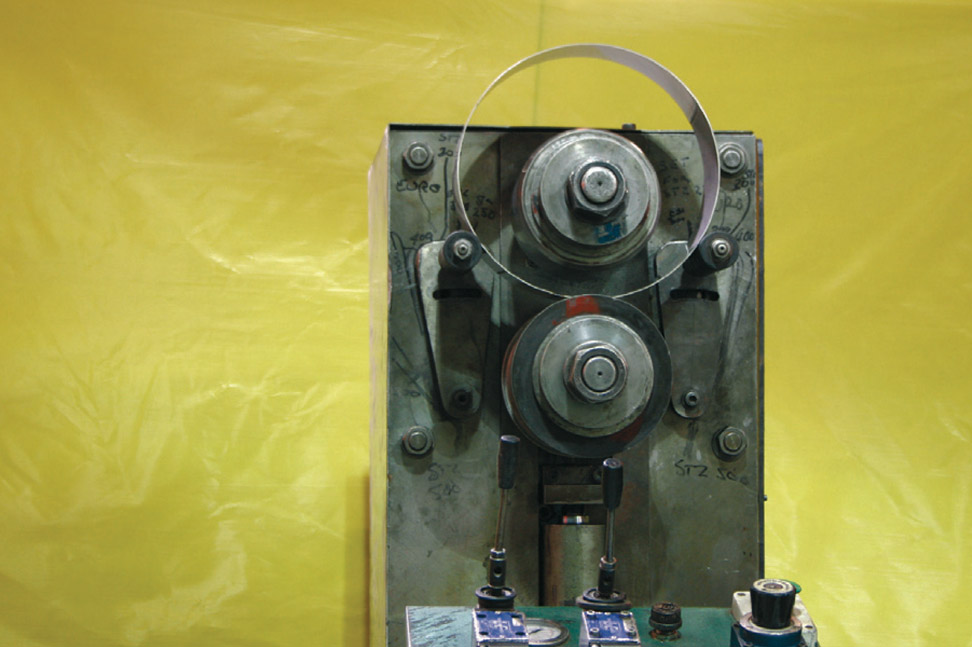

For producing steel housings (type B), first we cut steel strip to the specified length.This is the rolled to circular shape and TIG welded in that position. To make the housing more rigid, often the steel is given a profile by cold rolling. The materials most in use are the following grades of Stainless steel 1.4571 (AISI 320), 1.4404 (AISI 316)or 1.4301 (AISI 304).

Sealing Element of the Jacking Pipe Coupling or Inner Liner

Depending on volume and size of the coupling, the rubber part can be moulded or extruded. Extruded parts will have at least one vulcanised rubber joint. The effective sealing of the joint is obtained by both a lip and compression sealing areas of the rubber element. The choices of compression will be in such a way that water tightness over a long period is guaranteed and that the coupling can be joined to the pipe with an acceptable push- in force.

The rubber we use is mainly EPDM. The special formula was developed for sealing systems and has proven capability over long-term use. Other elastomers such as SBR and NBR can also be used.